.png)

Faster. Simpler. Better.

Specialist downhole technology & services for Well Exploration, Workover & Well Abandonment

.png)

Faster. Simpler. Better.

Specialist downhole technology & services for Well Exploration, Workover & Well Abandonment

We are pleased to announce that Ardyne is now part of Weatherford. Together, we now present the industry’s most comprehensive portfolio of plug and abandonment and slot recovery solutions, designed to extend productive well life and maximize asset value before final decommissioning.

Casing Recovery – Cut and Pull

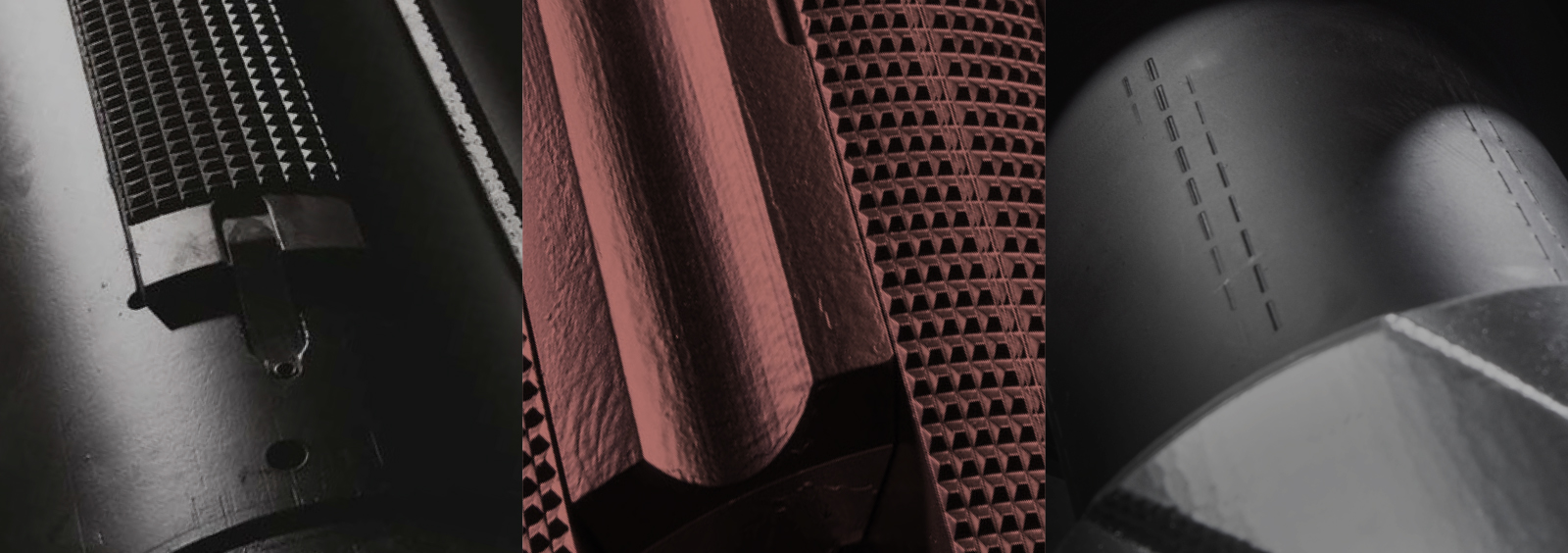

In addition to conventional casing cutters and spears, Ardyne has developed systems for casing recovery which save rig time and bring solutions for challenging operations.

Ardyne's Trident System is an integrated, single-trip casing cutting and pulling system, developed to save rig time, while offering a precision approach and additional functionality particularly useful for subsea operations.

The TITAN system gives repeatable, on-demand casing cutting and jacking capability in a single trip.

The TITAN System includes the Downhole Power Tool, and the Typhoon Spear:

- The Downhole Power Tool offers high pulling force applied directly to the fish, helping to assure casing recovery in problem applications.

- The self-locating Typhoon Spear can be mechanically or hydraulically released, and enables single trip casing recovery.

Casing Removal – Milling

Ardyne offers a full range of standard mills for casing removal, and is developing next generation milling technologies

Rigless

Ardyne is developing bottom hole assembly (BHA) technology to enable P&A and Slot Recovery from unconventional surface packages including coil tubing, snubbing units, hoist and workover units, rigless platform units and vessels with a derrick.

Cement Thru Cut & Pull BHA

The Ardyne developed Shogun System is a modular multi-function cement through cut and pull BHA.

It allows for a number of time and trip saving benefits.

Conductor Cut & Recovery

Ardyne TRIDENT FB System

Built to address the need for a reliable & efficient conductor cutter & spear, with a knife sweep from 30" up to 42". Bringing time savings to decomissioning with improved cutting times and increased spear setting / releasing reliability.

Economically Restore Annular Cement Integrity

Introducing the ACE Tool (Ardyne Casing Expander).

Designed to fix annular cement leakage behind the casing causing SACP (Sustained Annulus Casing Pressure) or an inability to place a well barrier plug inside the casing for temporary or permanent abandonment.

Using Resonance to free stuck casing

The Ardyne developed ART - Ardyne ReSonance Tool - enables the pulling of casing with resonance assist. Dynamically amplified vibration is transferred to the stuck casing through a casing spear in order to vibrate the settled solids, reducing the bond strength and friction. Therefore reducing the required pulling force to free the stuck object.

What we do

Ardyne develops and supplies specialised technology and services to the global energy industry, focusing on reducing rig time spent on downhole casing removal in slot recovery / re-entry, workover, and plug & abandonment operations throughout the well life cycle.

Our technology is brought to market using a variety of commercial models to meet our customers needs - from full service solutions where we provide direct to operators, to fully supported rental or sale of technology to service providers. Ardyne technology is safely and efficiently reducing rig time, lowering costs and unlocking value from assets, resetting the standard for casing recovery worldwide.

Overview of the technology available from Ardyne from fully commercialised systems and their next generation iterations, to newly developed technology which can provide operators with operational time savings for their P&A and Slot Recovery programmes.